Wrap spring technology used in Reell clutches provides the capability to transmit a large amount of torque in a small size. The package size for a given load rating is smaller for electric wrap spring clutches than other clutch technologies such as friction disk, tooth or magnetic particle. It also require less power for a given torque than these other technologies. Mechanical wrap spring clutches require only a small amount force for actuation.

Electric wrap spring technology has very positive engagement characteristics, meaning once the spring has wrapped down, the clutch will bring the system output up to speed in just a few milliseconds. Slip during engagement is virtually eliminated, resulting in the ability to cycle the clutch multiple times per second. Disengagement is also almost instantaneous, even under load.

Electric wrap spring clutches are ideally suited for critical timing applications requiring consistent, repeatable engagement and disengagement performance. Reell’s patented clutch design limits the effects of wear, so the timing performance remains constant throughout its rated life as opposed to other technologies which see increased timing variation as the load-driving surfaces wear. For high hour and/or input revolution applications, Reell has developed a long-life version, which dramatically extends the life of the clutch.

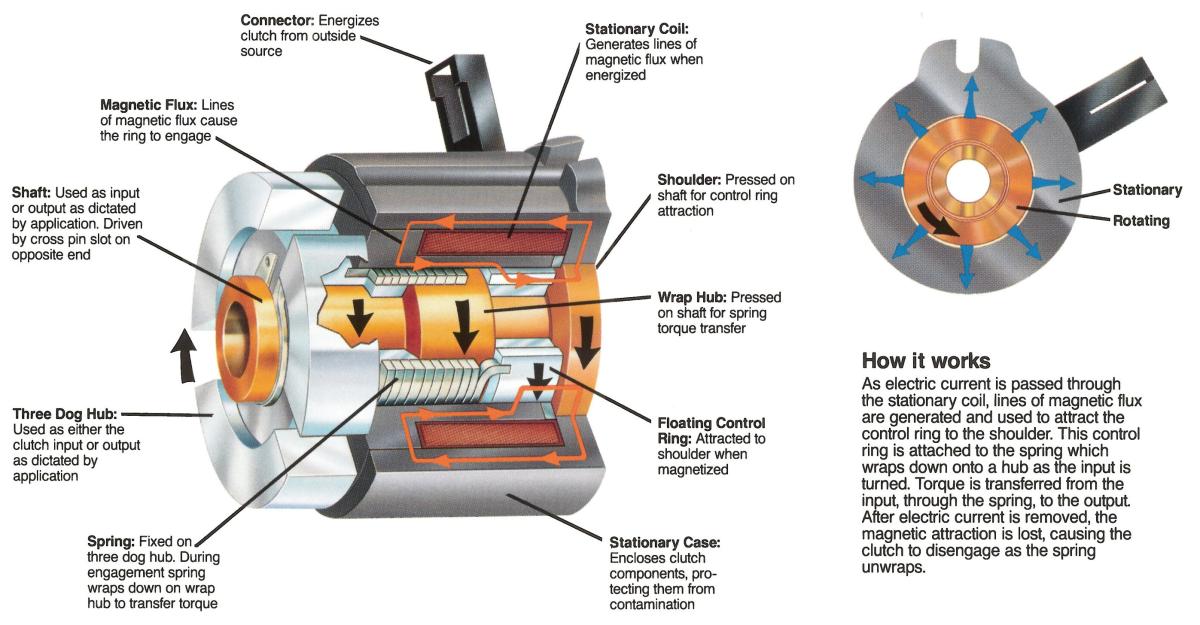

How Reell Electric Wrap Spring Clutches Work

As electric current is passed through the stationary coil, lines of magnetic flux are generated and used to attract the control ring to the shoulder. This control ring is attached to the spring which wraps down onto a hub as the input is turned. Torque is transferred from the input, through the spring, to the output. After electric current is removed, the magnetic attraction is lost, causing the clutch to disengage as the spring unwraps.

Slip Devices

Reell also uses wrap spring technology in its slip device products. Our unique design provides consistent torque over life, and comes in a variety of torques and sizes. These products can be used in conjunction with Reell’s wrap spring clutches or as stand-alone devices. Typical uses include system protection against high inertia shock, overload protection, or as a safety device for jammed conditions.