Friction Hinge Basics

Friction Hinge Basics

What Is a Friction Hinge?

Friction hinges, sometimes called torque or position hinges, are specially designed using resistance to control the motion of pivoting objects. Friction hinges are used to hold doors, panels, lids and screens solidly in position at any given angle, as well as determining the force required to move them.

To better conceptualize what a friction hinge is, think about the pivoting motion of laptop screens — one of the most common friction hinge applications in everyday life.

How Do Friction Hinges Work?

Unlike ordinary hinges, friction hinges are designed to provide rotational resistance. In order to achieve this, a special friction mechanism is used inside the hinge which restrains the hinge’s pivoting motion, ensuring a specific amount of force is required to open or close the object.

To suit a variety of applications, friction hinges are available in many forms, including:

Image

| |||

|---|---|---|---|

How Much Weight Can a Friction Hinge Hold?

Friction hinges can be made from a number of different materials, helping to determine their load-bearing capacity. However, it’s important to first focus on torque, not materials.

The torque, or rotational resistance of a friction hinge determines how it will function in an application, providing a smooth, controlled motion, while also holding components solidly in their desired position. The amount of torque needed from a friction hinge depends on several factors, such as:

- The weight of the object being held

- The distance between the axis of rotation and center of gravity

- The angle of the object relative to parallel

Reell's largest hinges can hold up to 11.3 N-m each, or 22.6 N-m for per pair. There is no “standard” weight this translates to, as weight is only one of the factors determining the necessary torque for your application.

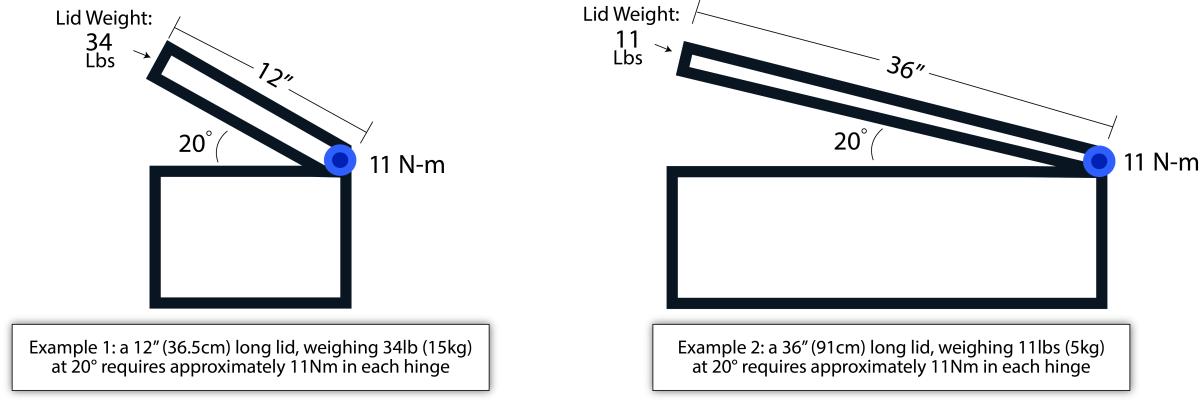

For example, consider two different scenarios when holding a lid at 20° above parallel using two friction hinges. In each case, consider the weight of the lid evenly distributed so the center of gravity is exactly in the center and the lid has 2 hinges:

To calculate your torque and to find the right hinge for your application, check out our Hinge Selection Guide!

Common Materials Used for Friction Hinges

Friction hinges are available in a variety of materials. The right material for your needs depends on the application requirements. Metal friction hinges may provide the strength needed, or nylon options may be needed for weight conscious applications. Every material has its own set of properties, offering unique benefits.

Zinc friction hinges provide a cost effective solution with a good balance of strength and design flexibility. For improved visual appearance or chemical resistance, zinc friction hinges can be painted or coated.

Stainless steel friction hinges are strong, durable, and resistant to corrosion and oxidation. Many people turn to stainless steel friction hinges for outdoor use, where there is the possibility of exposure to moisture, salt, UV light and other harsh elements.

Aluminum friction hinges are also resistant to corrosion and oxidation, much like stainless steel, but have a much higher strength-to-weight ratio. This makes aluminum friction hinges ideal for reducing weight without sacrificing durability.

Glass-filled nylon friction hinges offer lower cost and greater versatility than metal hinges. These hinges provide an aesthetically pleasing and economical option for applications where weight is important and the strength of metal may not be required. Nylon can be used in traditional hinges, specially designed monitor mounts, and more.

How Long Do Friction Hinges Typically Last?

Friction hinge cycle life determines how long until the product fails to hold position as intended. Failure can lead to falling lids and potential injury. Some friction hinges last longer than others so look for products with rigorous testing and qualification. Lower priced products may last a few hundred cycles while some solutions may perform acceptably for thousands of cycles in various environments. In comparison, Reell friction hinges are engineered with patented ReellTorq® clip technology, providing consistent long-life, zero-adjustment performance of up to 50,000 cycles.

Common Friction Hinge Applications

Engineers use friction hinges where ever they need a pivoting motion or secure positioning. This includes laptop screens, equipment lids, furniture, monitor adjustment, self serve kiosks, lighting and medical devices.

Friction hinges are common in the transportation industry, used in airplane and bus headrests, tray tables and compartments, automobile center consoles, in floor storage, or adjustable mirrors and screens.

Choose the Right Friction Hinge

When selecting a friction hinge, consider a multitude of factors — including all the requirements of your application, along with the conditions it will be subjected to. These considerations include:

- Weight, load and size requirements

- Hinge location and angle

- Orientation and rotational axis

- Life cycle requirements

- Environmental conditions and chemical exposure

- Aesthetics and design factors

Can You Design Your Own Friction Hinge?

At Reell, it’s easy to connect with engineers to start designing a custom friction hinge. Fill out the contact form or view existing Reell hinge solutions to see if any existing product might fulfill your needs.